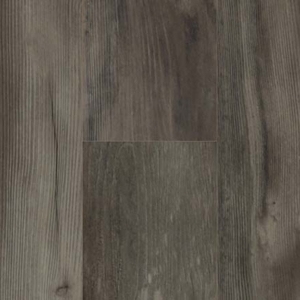

Deckhouse 850-860 Collection

[Registered Embossed | Laminate | 13.5MM #819-#824, #854-#860 / 13.8MM #830-#834]

LIMITED WARRANTY

Finish: Lifetime

Commercial: 10 Year Limited

SERIES INFORMATION:

#850 RE-LAM-#853 RE-LAM

Species/Janka| Oak |

|

Thickness| 13.5MM |

|

Width| 7 3/4” |

|

Length| 2’6”-7’4” |

|

Wear Layer| AC4 |

|

SF/BOX| 28.48 |

|

BX/PLT| 35 |

|

SF/PLT| 2206.8 |

|

BX/WGT| 63 |

|

SF/WGT| 2.23 lbs |

|

Waste %| 4-6% |

|

#858 RE-LAM-#860 RE-LAM

Species/Janka| Oak |

|

Thickness| 13.5MM |

|

Width| 7 3/4” |

|

Length| 2’6”-7’4” |

|

Wear Layer| AC4 |

|

SF/BOX| 28.48 |

|

BX/PLT| 35 |

|

SF/PLT| 2206.8 |

|

BX/WGT| 63 |

|

SF/WGT| 2.23 lbs |

|

Waste %| 4-6% |

|

#854 RE-LAM-#857 RE-LAM

Species/Janka| Hickory |

|

Thickness| 13.5MM |

|

Width| 7 3/4” |

|

Length| 2’-6” |

|

Wear Layer| AC4 |

|

SF/BOX| 22.93 |

|

BX/PLT| 35 |

|

SF/PLT| 1774.5 |

|

BX/WGT| 50.7 |

|

SF/WGT| 2.21 lbs |

|

Waste %| 4-6% |

|

INSTALLATION:

ADDITIONAL INFORMATION:

Core Construction| High-performance water-resistant laminate |

|

Core Type| Brown Core |

|

Joint System| EZ - Drop 5G Click |

|

Texture| Registered Embossed (EIR) |

|

Edge Profile| Painted Bevel |

|

Finish Type| AC4 Melemaine wear layer |

|

| Pattern Repeat #850-853: 9+ / #854-860: 12+ |

|

Gloss Levels| 5% - 7% |

|

Maintenance| Zep Neutral Floor Cleaner |

|

Repair Finish| N/A |

|

Expansion Requirements| 5/16” expansion gap for the first 20 lineal feet (length or width). Add additional 1/16” for every 5’ of install (length or width) up to 5/8”. T-molds are required for rooms exceeding 50 lineal feet in length and width and 40 lineal feet for installations over in floor radiant heat. |

|

Uses| Residential - Commercial |

|

COMPLIANCE:

COMMON QUESTIONS:

GENERAL SUBSTRATE REQUIREMENTS

Structurally sound, well bounded, flat to within 3/16” in 10’ radius or 1/8” in 6’ radius, vertical deflection cannot exceed 1/4” in 10’ radius, or more than 1/16” between the floor joists.

APPROVED SUBSTRATES (DECKHOUSE LAMINATE)

(Floated only option) Subfloors over joist systems: Must be TECO or APA subfloor grade CDX plywood/OSB. The joist span cannot exceed 16” on center when using 5/8” CDX plywood or 3/4” 40lb OSB, 19.2” on center when using 3/4 plywood or 3/4” 40lb OSB, or 24” on center when using 7/8” plywood or 1” 40lb OSB.

(Floated only option) Additional approved substrates: Cured concrete over 3000 PSI, cured gypcrete over 2500 PSI., cement backer board, cementitious & anhydrite screeds, radiant heated subfloors that do not exceed 85°F surface temperature, & gypsum or lightweight concrete (primed with TuffGrip LSP Primer). (See TG-9 for additional approved substrates.)

WOOD SUBFLOOR (EMC) MOISTURE CONTENT REQUIREMENTS

The subfloor must not exceed 12% MC (moisture content). Wood subfloors must be suspended a minimum of 18” from the ground with adequate ventilation. The ground surface of the crawl space must be covered with a minimum of 6 mil plastic (puncture resistant) vapor barrier.

CONCRETE/GYPCRETE MOISTURE EMISSIONS, RH, & PH REQUIREMENTS

(For BELOW, ON, or ABOVE GRADE) If floated – Properly install a minimum of 6 mil plastic over the entire concrete or gypcrete substrate. Overlap all seams 12” & tape all seams with moisture-proof tape. The concrete or gypcrete must have a pH test between 5 to 9.

JOBSITE CONDITION RANGES

The Jobsite RH must be maintained between 30%-60% & the room temperature between 55°-85°F before, during, & after installation.

ACCLIMATION TIMEFRAME

Acclimate for a minimum of 48 hours to reach room temperature between 55°-85°F.

CAN WE INSTALL A CUSHION UNDERNEATH THE FLOOR?

This product has an attached 1.5mm thick high-density EVA cushion. Any additional cushion is not approved.

RECOMMENDED GLUE

Not approved.