QUICK, EASY INSTALLATION

The Välinge 2G Angle/Angle system is a patented locking profile for installing flooring planks without using glue.

TuffCore WPC Installation Guide

TABLE OF CONTENTS

[01] GENERAL JOBSITE/HOME CONDITION

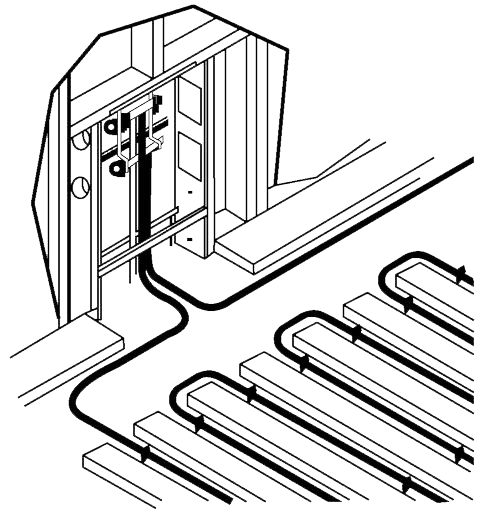

[02] IN-FLOOR RADIANT HEAT REQUIREMENTS (HYDRONIC SYSTEM ONLY)

[03] IN-FLOOR RADIANT HEAT MOISTURE BARRIERS AND RETARDERS

[04] GENERAL INSTALLATION SPECS

[05] GENERAL SUBSTRATE CONDITIONS

[06] APPROVED SUBSTRATES

[07] ACCLIMATION (FOR RADIANT HEAT SEE “IN-FLOOR RADIANT HEAT ACCLIMATION REQUIREMENTS” SECTION)

[08] EXPANSION REQUIREMENTS

[09 FL] APPROVED FLOATING METHOD (ESTATE UNILIN DROP-N-LOCK SYSTEM)

[10] HOW TO PROTECT THE FLOOR DURING & AFTER INSTALLATION (DURING CONSTRUCTION)

For the most up-to-date installation, maintenance, and warranty requirements, please visit www.my-nfp.com. All warranties are based on installation and maintenance guides published on our website at the time of installation.

The intended end user and the installer should have a clear understanding of the expectations of the color, installation, and layout. Carefully inspect the products before installation for any milling, dimensional, or visual defects. If the flooring supplied does not satisfy the customer, do not proceed to install it. The decision not to proceed must be made within the first 10%, or 100 sq ft., of the flooring boxes opened, whichever comes first; open boxes exceeding this amount will not be eligible for return.

[01] GENERAL JOBSITE/HOME CONDITION

TO AVOID COSTLY INSTALLATION MISTAKES, ONLY INSTALL FLOORING IN ROOMS UNDER ADEQUATE LIGHTING CONDITIONS

Important: The requirements listed below are considered standard practices for the flooring industry and are required by most building codes. Following these simple guidelines will greatly extend the life of any fixture in the job site/home. Local building codes may vary and will prevail.

- It is the responsibility of the designated installer to inspect the flooring before installation. Inspect every plank for inconsistency with the finish, texture, milling, color, graining, tongue and groove integrity, and dimensions. Also, check the suitability of the flooring product to its environment. Flooring products installed with pre-existing defects, or that were incorrectly acclimated, CANNOT be claimed after installation.

- Verify there are enough materials to complete the job with a minimum of 2% extra for future plank replacements.

- Allow a minimum of 5% waste for culling, shipping damage, and on-the-job waste.

- Make sure the crawl space has at least 18” clearance from the dirt to the bottom of the beams. Remove all cardboard from the concrete walls, pillars, and footings as it will trap and hold moisture. The entire crawl space must be covered with a minimum of 6 MIL puncture-resistant plastic vapor barrier with all seams overlapping the 18”, fully sealed with moisture-proof tape. [The instructions were unclear here – what did you mean by the previous instructions?]

- To prevent excessive moisture buildup, all crawl spaces must have a minimum of 1.5 sq ft. of ventilation for every 100 sq ft. of crawl space at the exterior of the house for cross ventilation or an air exchanger will be needed. It may be necessary to install temperature/humidity-activated exhaust fans to create air movement in the crawl space.

- Drainage from roofs, rain gutters, and other sources of moisture around the job site/home must be directed away from the site.

- All exterior doors, windows, drywall, painting, and venting must be properly installed before the delivery of the flooring to the job site/home. Do not store material in exterior sheds, garages, or rooms that are not temperature-controlled.

- All heating and cooling systems are required to be installed and functioning for at least 14 days before installation begins.

- Use a hygrometer that reads temperature and RH (relative humidity) to check job site/home heating and cooling systems. They must be able to maintain a minimum of

- 30% to 60% RH and 60° to 85°F before, during, and after the installation.

- Small humidifiers are not capable of properly maintaining the humidity levels in large job sites/homes. Your local heating and cooling air service contractors can provide information for automatic humidifiers/dehumidifiers that work with your heating and cooling systems.

- WPC flooring is not recommended to be installed in any area of the job site/home that has extreme temperature and moisture fluctuations. For example: saunas, hot tub/pool rooms, green houses, exterior porches, or garages. The manufacturer does not cover these types of moisture-related issues or related damages under their warranty.

[02] IN-FLOOR RADIANT HEAT REQUIREMENTS (HYDRONIC SYSTEM ONLY)

Visit www.my-nfp.com for the current list of products that are approved for in-floor radiant heat. There are unique installation requirements for flooring installed over radiant heat. Before installation, it is the responsibility of the job site/homeowner-designated installer to check with the manufacturer for a current list of approved installation methods and underlayment requirements. All warranties are based on installation and maintenance guides published on our website at the time of your installation.

IN-FLOOR RADIANT HEAT SYSTEM REQUIREMENTS:

- Only flooring that is marked approved can be installed over in-floor radiant heat.

- Only hydronic in-floor radiant heat systems with failsafe capabilities (to ensure the boiler does not exceed 110°F and the surface temperature does not exceed 85°F) are approved.

- Operate the in-floor radiant heat system for at least 14 days before the flooring is installed. All moisture in the substrate MUST be evaporated off. This will also ensure all systems are in good running condition.

- To prevent expansion and contraction issues related to the in-floor heat system, a humidity-control humidifier must be

- installed and properly functioning before, during, and after the installation.

- Transition strips/breaks are required over in-floor radiant heat substrates exceeding 35 feet lengthwise and widthwise.

- Important: Leave a 1/2” expansion gap around all walls, tubs/ showers, plumbing fixtures, exterior doors, and large Sub-Zero style refrigerators or appliances.

- The in-floor radiant heat systems CANNOT be installed directly below the flooring. The heating element must be embedded at least 1/2” into the concrete, gypcrete, or installed under the wood subfloor. This will ensure the radiant heat is evenly distributed across the substrate before the heat comes into contact with the flooring.

IN-FLOOR RADIANT HEAT ACCLIMATION REQUIREMENTS:

- Do not deliver the flooring to the job site until all environmental conditions have been met.

- Acclimate for a minimum of 48 hours in the temperature-controlled room where it will be installed.

- During acclimation, do not remove the material from the box or lean boxes on walls. Only stack the boxes squarely on top of each other, no taller than 3’, and keep the stacks at least 3” apart.

- It is required to reduce the subfloor surface temperature down to 65°F a minimum of 72 hours before installation.

- After the installation, raise the temperature slowly to the desired conditions. It is not recommended to raise or lower the temperature by more than 5°F in 24 hours.

- To prevent the floor from overheating or trapping moisture, never cover the flooring before, during, or after installation with any non-breathable or excessively thick rugs, mats, solid surface items, plastics, or mattresses laid directly onto the floor. The floor must be allowed to breathe.

IN-FLOOR RADIANT HEAT-APPROVED INSTALLATION METHODS:

- See the approved substrate portion of this guide for all substrate requirements.

- Floating installations are approved for substrates with in-floor radiant heat.

- Glue-down installations are approved for substrates with in-floor radiant heat. Be sure to follow the adhesive manufacturer’s substrate requirements for surface preparations, moisture testing and mitigation, primers for concrete/ gypcrete, and installation instructions. Bond warranties come solely from the adhesive manufacturers.

[03] IN-FLOOR RADIANT HEAT MOISTURE BARRIERS AND RETARDERS

The type of moisture barrier is usually based on the installation method and substrate. Different types of moisture barriers produce the same result by doing it differently. Check with local building codes and the manufacturer of the radiant heat systems for recommendations.

WPC WITH ATTACHED CORK (IN-FLOOR RADIANT HEAT):

- Below, On, or Above Grade Concrete & Gypcrete Slabs: Cover the entire slab substrate with 6 mil plastic with all seams overlapping per 12” and taped with moisture-proof tape.

- Wood Subfloors: A moisture barrier is not required over a finished basement or crawl space that meets the “General Jobsite/Home Condition” requirements.

Prop 65 Warning: Drilling, sawing, sanding, or machining wood products generates dust, a substance known to the state of California to cause cancer. Use caution during the removal or sanding of existing flooring or other building materials as these may contain hazardous fumes, and chemicals, or generate harmful dust. Check the substrate for any health hazards. Always wear safety equipment and an approved dust mask.

[04] GENERAL INSTALLATION SPECS

- Avoid installing flooring plank pieces less than 8” in total length against walls or on ends. Stagger end joints no less than 8”.

- It will generally be necessary to see some flooring panels during installation. To obtain a clean cut, the pattern side should face down when using a jigsaw, saber saw, or circular handsaw and face up when using a handsaw, table saw, or crosscut saw.

- Before installation begins, use a jamb saw to undercut all door casings (1/16” between the door casing and the top of flooring material) and vertical objects coming off the floor. To achieve the correct height, combine a piece of the vapor retardant and flooring to guide the saw. Be sure to clean out all debris from under the jambs. This will allow the flooring to slide underneath the object for a clean and professional look.

- Contractors: When setting door casings post-installation, ensure adequate space for the flooring to expand and contract without any hindrance.

- Never fasten nails, screws, or anything through the flooring into the substrate. The floor MUST be allowed to float freely.

- For a perfect finish around pipes, use rosettes in places where profiles or skirting cannot be placed.

- Do not caulk the floor with any permanent or fixed object. The floor must be allowed to float freely.

[05] GENERAL SUBSTRATE CONDITIONS

- All substrates must be flat, structurally sound, and free of dust, loose particles, paint, and drywall compounds.

- Sand and/or flatten the substrate to within a 3/16” dip or rise in a 10’ or 1/8” dip or rise in a 6’ radius.

- If leveling of the substrate is required, use only cement-based leveling compounds. Be sure to follow the leveling compounds manufacturer installation guidelines.

- WPC flooring can be installed over wood subfloors that are ON or ABOVE GRADE; WPC following can be installed over concrete or gypcrete substrates that are BELOW, ON, or ABOVE GRADE.

- When walked on, the substrate must not exceed 1/4” deflection in a 6’ radius, or more than 1/16” between the floor joist. If it does, this condition must be corrected before any product installation begins. If not corrected, the subfloor will not stiffen up after the flooring is installed.

- Always check and repair any loose, delaminating, or broken substrates.

- Hand-held angle grinders with special cupped diamond grinding wheels and vacuum attachments can be rented or purchased from your local rental or home-building center. This system works well with any type of substrate. Use precautions when sanding any surface. Check the substrate out for any health hazards, and always wear safety equipment and an approved dust mask.

[06] APPROVED SUBSTRATES

PLYWOOD/OSB:

- Do not install overwood subfloors that test above 12% MC (moisture content).

- Note: If installing new wood subfloors from lumber yards, be sure to test the MC. Typically, they have higher levels of moisture and may need to acclimate longer. Issues caused by this condition are not covered by any manufacturer warranty.

- Fix all squeaks coming from the wood subfloor prior to installation. Use wood screws, a minimum of 2-1/2” long, fastened every 6” through the wood subfloor into the joist. Squeaks in the subfloor will not go away after the floor has been installed.

- The acceptable minimum thickness of the wood subfloor is determined by the distance between the joists/trusses. Vertical deflection must be under 1/4” in a 6’ radius when walked across.

-

- When joists are 16” o/c or less; the minimum acceptable thickness is 5/8” CDX plywood or nominal 3/4”, OSB 40LB Minimum density, T&G, with a TECO or APA certification stamp.

- When joists are 16” o/c up to 19.2” o/c; the minimum acceptable thickness is 3/4” plywood or nominal 3/4”, OSB 40LB Minimum density, T&G, with a TECO or APA certification stamp.

• When joists are 19.2” o/c up to 24” o/c; minimum

acceptable thickness is 7/8” plywood or nominal 1”,

OSB 40LB Minimum density, T&G, with a TECO or

APA certification stamp

CURED CONCRETE/GYPCRETE: (6MIL PLASTIC VAPOR BARRIER IS RECOMMENDED TO AVOID MOISTURE-RELATED ISSUES)

- Cured concrete must be over 3000 PSI. Cured gypcrete must be over 2500 PSI.

- All concrete or gypcrete substrates must be cured for a minimum of 60 days before any flooring product is installed over them.

- Concrete moisture testing should be performed by ASTM F1869 Calcium Chloride Tests with levels NOT exceeding 5LBS per 1000 ft2 for 24 hours, or an ASTM F2170 In-Situ relative humidity test with readings exceeding 80%.

- Gypcrete dries very fast so Maxxon recommends using the mat test or Delmhorst #B2100 moisture meter.

- Test the concrete subfloor for alkalinity. (The pH of the floor must be between 5 and 9).

PARTICLE BOARD (UNDERLAYMENT-GRADE):

- Some adhesive manufacturers will warrant a WPC floor glued down over underlayment-grade particle board. Follow their glued-down installation instructions since the bond warranty would come solely from them.

- The only manufacturer recommended installation method that can be used directly over underlayment-grade particle board is the floating method, as long as there are no current or future moisture concerns from below or above. If moisture comes in contact with the particle board, it may swell. The product warranty does not cover subfloor upheavals.

OTHER APPROVED SUBSTRATES (FLOATING ONLY): (ALL MOISTURE CONTENT, FLATNESS AND DEFLECTION REQUIREMENTS WOULD APPLY.)

- Ceramic, porcelain, or natural tile with the grout joints filled flat with Portland-based patching material.

- A single layer of clean, well-adhered, non-cushioned, full-spread glue sheet vinyl or VCT. All embossing must be feathered and filled with a suitable filler patching compound.

UNACCEPTABLE SUBSTRATES:

- Solid or engineered wood floors over concrete.

- Floors that are floating, cushioned, perimeter glued, carpet, carpet pad, lumber subfloor, or subfloors that are sticky.

- ACQ-treated plywood or exterior low-density OSB sheeting is used for general construction.

[07] ACCLIMATION (FOR RADIANT HEAT SEE “IN-FLOOR RADIANT HEAT ACCLIMATION REQUIREMENTS” SECTION)

- Installing flooring before it has properly acclimated will greatly increase the chances of expansion and contraction issues and may make it more difficult to install.

- Do not deliver the flooring to the job site until all environmental conditions have been met.

- Acclimate for a minimum of 48 hours in the temperature-controlled room where it will be installed.

- During acclimation, do not remove the material from the box or lean boxes on walls. Only stack the boxes squarely on top of each other, no taller than 3’, and keep the stacks a minimum of 3” apart.

- During installation, floor temperature should be within 65-85°F.

- Ensure flooring planks are at or near the room temperature of where the flooring is being installed.

- Never cover the flooring before, during, or after installation with any type of plastic or tar paper. It must be allowed to breathe. Use only breathable floor-protective construction paper (FortiBoard) to protect the flooring.

- Propane heaters are not an approved source of heat and can give off extreme amounts of moisture. They also do not provide a reliable and consistent source of heat. In fact, for every gallon of propane or kerosene that is burned, they will put approximately 1.1 gallons of moisture into the ambient space. The manufacturer warranty will be void if the job site/ home heating and cooling system is not fully operational at the time of installation.

- HVAC must be installed and running before the installation of the floor covering.

[08] EXPANSION REQUIREMENTS

- Leave a minimum of 1/4” expansion gap for all installations under 20’ lengthwise or widthwise. For installations exceeding 20’ lengthwise or widthwise, add 1/16” per additional 5’of length or width, up to 5/8”. For example: 25 linear feet would have a 5/16” expansion gap.

- T-molds are required for rooms exceeding 40 lineal feet in length and width; for installations over in-floor radiant heat, T-molds are required if exceeding 35 lineal feet.

- Never install cabinetry, islands, or other permanent fixtures on top of a floated floor.

- Never use nails to secure anything to the floor. The floor must be allowed to float.

- Leave the required expansion gap around all walls, tubs/showers, plumbing fixtures, and large Sub-Zero style refrigerators, exterior doors, etc.

- Once the floor installation is complete, remove all spacers that were used to maintain the expansion gap.

- Heavy furniture (500 lbs or more) may obstruct the free, natural movement of a floated floor. Restricting this movement in certain areas can lead to problems such as buckling or separation when the floor experiences natural expansion and/or contraction.

[09 FL] APPROVED FLOATING METHOD

(MARKET AND MAIN VALINGE 2G ANGLE/ANGLE)

The Valinge 2G Angle/Angle system is a patented locking profile for installing flooring planks without using glue.

Floating Method Tips:

- The panels are clicked together on the short side until the row is completed then the entire row is engaged on the long side.

- Be sure to inspect all edges and remove debris from the click before installing.

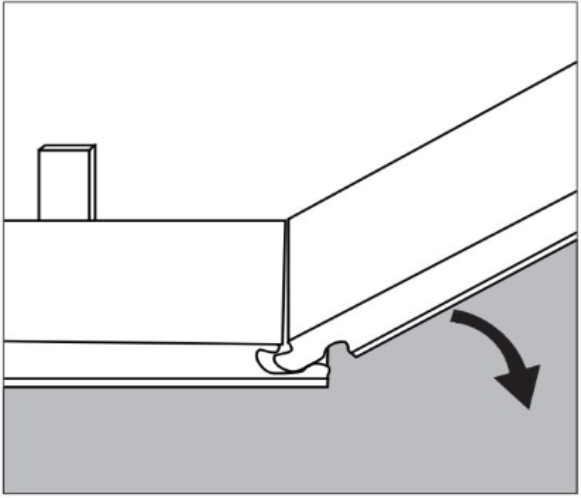

- Either side of the panels is engaged at an angle of 20° to 30° to the panel already installed. Move the panel gently up and down while exerting forward pressure, and the panels will automatically click into place. Then lay the plank down to the floor.

- As you install the click flooring, ensure all seams are fully engaged before moving on to the next row. Visually, a row can appear to be engaged but is not. To avoid this, use an approved tapping block to tap the short side and then the long side of the planks together. This will securely engage the locking system.

[09 GD] APPROVED GLUE-DOWN METHOD

(MARKET AND MAIN WITH ATTACHED CORK)

APPROVED ADHESIVES:

- Follow all substrate, moisture content, and expansion requirements outlined in sections 1-8 of this guide.

- All adhesive and bond warranties come solely from the adhesive manufacturer. Follow all of the adhesive manufacturer guidelines regarding installation requirements.

- Use a good quality polymer-based adhesive like Tuffgrip PS99 Modified Transitional PSA or equivalent.

- Depending on the application the trowel size will vary. Follow the adhesive manufacturer’s recommendation for 7.5mm WPC with attached cork. Using the full spread method, be sure that the adhesive is adhered completely to the bottom of the flooring.

- Periodically, check to make sure the trowel notches are clean and not worn out. Also, verify there is adequate glue transfer to the back of the planks.

- It is not recommended to glue WPC flooring down over particle board subfloors unless the glue manufacturer approves it. Either remove the particle board or install new 1/4” thick plywood over the particle board, then install the new floor over the plywood.

- Be sure to remove wet adhesive from the surface before it dries and damages the finish. Most adhesives can be cleaned off of the floor surface with WF Taylor Touchdown #9 adhesive remover on a terry cloth rag, followed by a rinse with clean water on a rag. Do not pour cleaning products or adhesive removers directly onto the floor. Always test the cleaner before attempting to clean the floor.

GLUE DOWN TIPS:

- Working off the longest straight wall (typically an exterior wall), snap a chalk line parallel with the wall that is equal to the width of the flooring plus enough room for the expansion gap. Use spacers to maintain the proper expansion gap.

- Keep the groove side facing out.

- If needed, use only green/blue 3M/Scotch Tape model #2080 to hold the floor together while the adhesive is drying for a minimum of one hour and no longer than 24 hours. Do not use duct tape or packing tape as they can damage finishes.

- Allow the first rows to dry for a minimum of one hour before installing additional rows; this will ensure a solid and straight platform against installing the next rows.

- Avoid heavy foot traffic on the floor for a minimum of 24 hours to allow the glue to set properly.

- Once the floor installation is complete, remove all spacers that were used to maintain the expansion gap.

DO NOT WET OR CLEAN FLOOR FOR A MINIMUM OF 72 HOURS. THIS WILL ALLOW THE ADHESIVE TO CURE PROPERLY.

[10] HOW TO PROTECT THE FLOOR DURING & AFTER

INSTALLATION (DURING CONSTRUCTION)

The Valinge 2G Angle/Angle system is a patented locking profile for installing flooring planks without using glue.

- After each section of flooring has been installed and thoroughly cleaned, cover the floor with breathable protective construction paper (FortiBoard). Do not apply the tape directly to the surface of the flooring, as it may damage the finish.

- During construction, vacuum the floor as often as it takes to keep the floor free of dirt and construction debris. Never use a beater brush.

- If drywall repairs or any type of sanding is needed, thoroughly cover the floor. These types of dust and grit can damage the floor’s finish and are very difficult to remove if they get into the joints. Do not wet mop these types of dust. Always use a vacuum without a beater brush to remove any construction dust if needed.

- Before furniture goes onto the new floor, apply approved 3/16” thick heavy-duty felt pads under all furniture feet.

- Furniture with metal or hard plastic rollers or casters is NOT APPROVED for use on WPC flooring.

- Never roll or drag anything heavy over the new floor; it will make indentations or scratches on the surface. When moving objects, always use a soft-tire dolly, a carpet piece turned upside-down, or an air-sled.

Note:

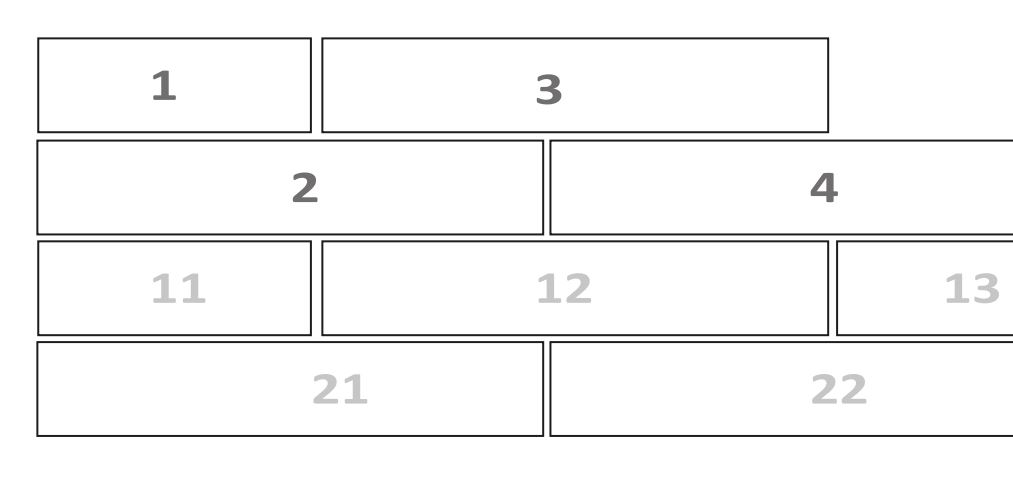

Products should be staggered in a bricklaid pattern, stagger equal to half of a plank for the first four rows, and randomly from row 5 on. Tools needed: pull bar, spacers, soft-faced hammer, and tapping block.

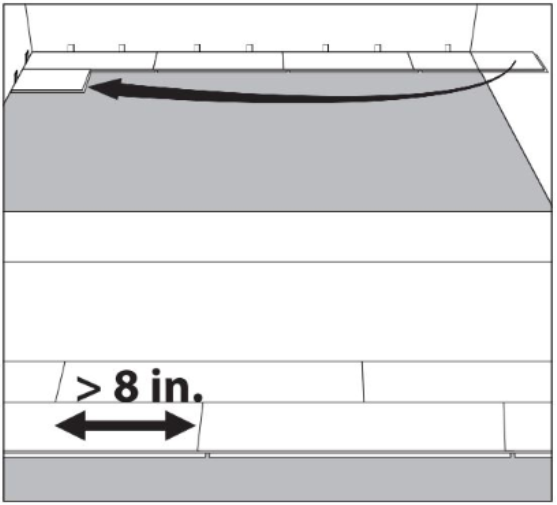

FIG. 1

Leave a minimum of 1/4” expansion gap for all installations under 20 linear feet and add 1/16” per additional 5’ of length for installations exceeding 20 linear feet. For example: 25 linear feet would have a 5/16” gap. The maximum continuance distance without a t-mold transition is 40’ in width or length. Insert spacers to create proper expansion gaps at ends and edges where the planks will meet the walls and any vertical objects.

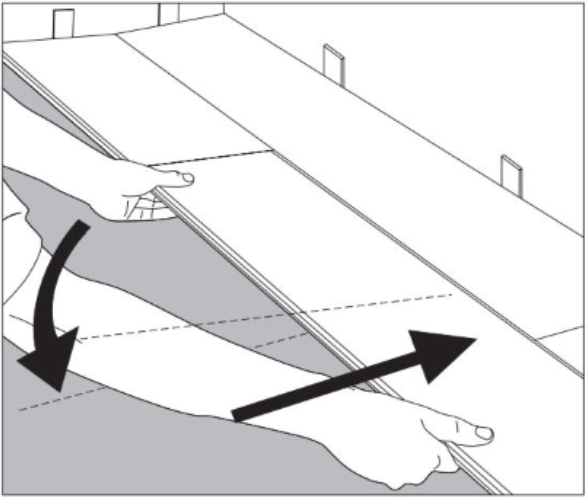

FIG. 2

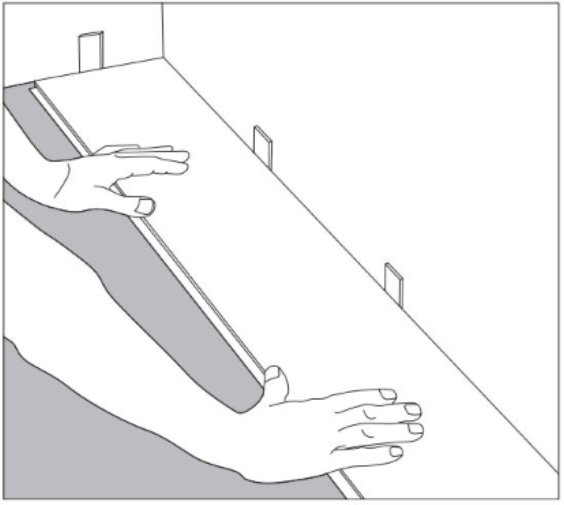

Start the first row by inserting the short end of the plank (tongue first) into the groove at 20° to 30° angle, then rotating downward to lock it in place. Continue laying planks to establish the first row.

FIG.

Use a cut piece to start the second row.

NOTE: End joint spacing must be at least 8” for all adjacent rows.

FIG. 4

For additional rows, engage the locking system on the short side of the last plank installed by inserting the tongue at a 20° to 30° angle, then rotating downward. Slide this plank toward the long side of the previously installed plank, then engage the long side of the plank. Lift the other side slightly, and push or pull the plank together until it clicks together.

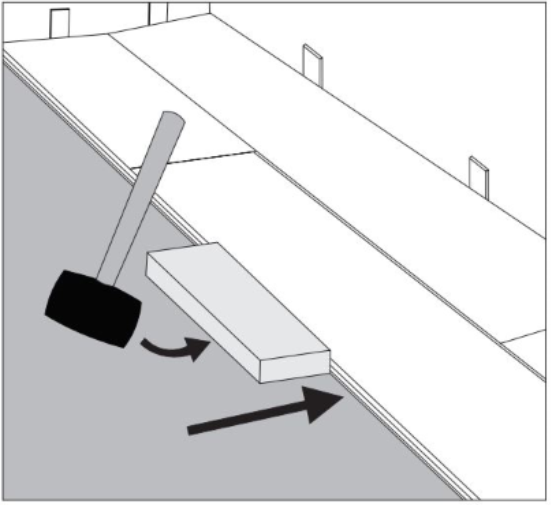

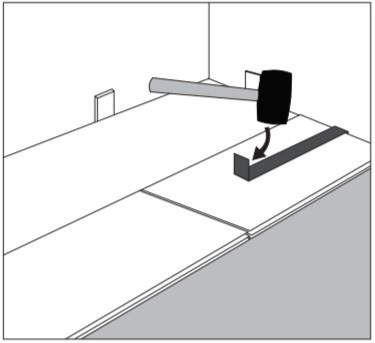

FIG. 5

Use a scrap piece of flooring as a tapping block and tap on the long edge of the plank to ensure that the locking system fully engages.

FIG. 6

Use a cut piece to start the second row.

NOTE: End joint spacing must be at least 8” for all adjacent rows.

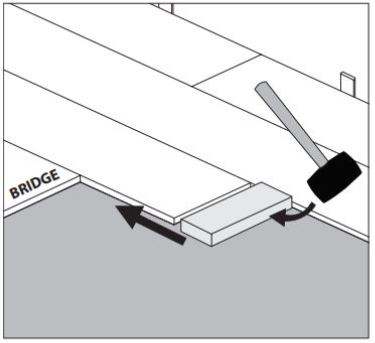

FIG. 7

Using a scrap piece (with a factory end joint) as a tapping block, tap the end of the plank to engage the locking system. Be cautious to not damage the locking profile when tapping. Continue installing until you reach the end of the row.

FIG. 8

At the end of the row, use a hammer and pull bar to engage the locking system of the final piece in the row. Install a spacer at the row end. Repeat this process until the final row of flooring.

At the final row, use the hammer and pull bar to lock the long edges of the planks as well as the row ends.

When completed, pull all spacers and double-check to ensure there is the required expansion gap.