Virginia Collection

[Hand Scraped | Solid | 3/4”]

LIMITED WARRANTY

Finish: 25 year

Structural: Lifetime

SERIES INFORMATION:

#352 HS-S, #355 HS-S

Species/Janka| Hickory (1780) |

|

Thickness| 3/4” |

|

Width| 5” |

|

Length| 1’-4’ |

*Quantity per length varies* |

Wear Layer| 3/16” |

|

SF/BOX| 22.60 |

|

BX/PLT| 48 |

|

SF/PLT| 1085 |

|

BX/WGT| 72 |

|

SF/WGT| 3.19 lbs. |

|

Waste %| 5-7% |

|

#459 HS-S-#464 HS-S

Species/Janka| Hickory (1780) |

|

Thickness| 3/4” |

|

Width| RW |

|

Length| 1’-4’ |

*Quantity per length varies* |

Wear Layer| 3/16” |

|

SF/BOX| 22.42 |

|

BX/PLT| 48 |

|

SF/PLT| 1076 |

|

BX/WGT| 70 |

|

SF/WGT| 3.12 lbs. |

|

Waste %| 5-7% |

|

#465 HS-S-#468 HS-S

Species/Janka| W. Oak (1280) |

|

Thickness| 3/4” |

|

Width| RW |

|

Length| 1’-4’ |

*Quantity per length varies* |

Wear Layer| 3/16” |

|

SF/BOX| 24.59 |

|

BX/PLT| 48 |

|

SF/PLT| 1180 |

|

BX/WGT| 67 |

|

SF/WGT| 2.72 lbs. |

|

Waste %| 5-7% |

|

INSTALLATION:

ADDITIONAL INFORMATION:

Core Construction| Solid Wood |

|

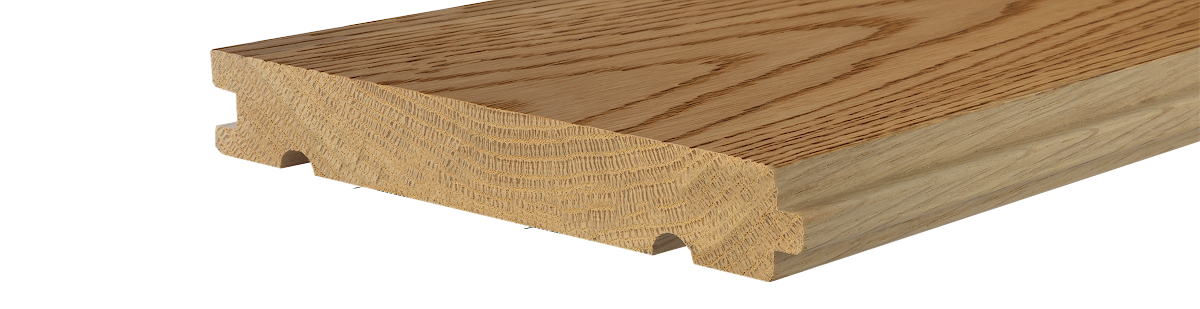

Joint System| Tongue and Groove |

|

Texture| Hand Scraped (Hand Crafted) |

|

Edge Profile| Hand Sculpted, Chattered, |

Pillowed Edge |

Texture| Smooth |

|

Finish Type| 9 Finish Coats - UV cured urethane infused with aluminum oxide |

|

Gloss Levels| 9%-12% |

|

Maintenance| Bona Hardwood Formula |

|

Repair Finish| Can be screened and recoated with Bona HD Traffic (or similar) |

|

Expansion Requirements| Requires minimum of 1/2” expansion gap around all fixed objects and walls |

|

| Fastener Requirements 15-16 gauge, L/T cleats, or 7/16” to 1/2” crown staples, minumum 1 3/4” Length. Fastener spacing 1 1/2” from the board ends and every 6” - 8” along the tongue |

|

Uses| Residential Light Duty |

Commercial |

COMPLIANCE:

COMMON QUESTIONS:

SUBSTRATE REQUIREMENTS

Structurally sound, well bounded, flat to within 3/16” in 10’ radius, or 1/8” in 6’ radius. Vertical deflection cannot exceed 1/4” in 10’ radius, or more than 1/16” between the floor joist.

APPROVED SUBSTRATES

Underlayment APA grade CDX plywood/OSB. See NWFA guidelines for 3000 PSI concrete or 2500 PSI gypcrete.

WOOD SUBFLOOR (EMC) MOISTURE CONTENT REQUIREMENTS

Solid wood MC (moisture content) must test within 2% of the wood sub-floor. Neither can exceed 12%.

CONCRETE AND GYPCRETE MOISTURE EMISSIONS, RH, AND PH REQUIREMENTS

Random width and/or narrower than 4 1/4” ONLY. Check with NWFA for an approved adhesive and/or moisture mitigation system for concrete/gypcrete, RH, pH, and installation requirements. (Bond and moisture mitigation warranties comes soley from glue and/or vapor barrier manufacturer.)

JOBSITE CONDITION RANGES

Prior, during, and after installation, the jobsite RH must be maintained between 35-55%, and the room temperature between 60-80°F.

ACCLIMATION TIMEFRAME

Minimum 72 hours to reach room temperature between 60-80 °F. The subfloor and the wood flooring MC (moisture content) must test within 2% of each other and does exceed 12%. If the MC falls outside this range, a longer acclimation period is required to reach equilibrium.

CAN WE INSTALL A CUSHION UNDERNEATH THE FLOOR?

Cushion is not compatible.

RUG COMPATIBILITY

Must be breathable, non abrasive, natural fiber rugs. Please see RugPadUSA.com. For example; Eco Plush 3/8”, Contour Lock, RugPro, or Superior Lock 1/4”.